A customer, lacking relevant industry experience in the early stage of her business, chosed a supplier with a lower price. However, after receiving the first batch of goods, they are deeply disappointed with the quality. Later, they turned to us, hoping to improve the quality of the products to the desired level. From that moment on, we started our cooperation with the principle of "controlling details, solving problems, and being open and transparent", rather than just a hollow slogan.

Before one shipment, we inspected each bag item by item according to the established process. During the zipper usage test, our quality control team (QC) found that the color of the pull tab was thinning at the contact point with the pull head. Prolonged friction might cause slight color fading. This seemingly minor detail could be magnified during consumer use, thereby affecting the customer's brand reputation and consumer experience.

Our QC team immediately reported the situation to the management. We did not choose to hide the problem or use other excuses to cover it up, but proactively contacted the customer and arranged a video conference for it. We truthfully demonstrated the testing process, the friction location and the basis for judgment, ensuring that the customer could see the detailed issue clearly. The customer stated that their target market is very picky about the details of the product, so they decided to optimize this issue before shipment to ensure that the product quality is impeccable.

After thorough communication, we reached a consensus with the customer. We decided to re-spray the color of the pull tab and replace all the pull tabs. At the same time, we conducted the zipper puller friction test again and strictly re-inspected the color fastness to ensure that the "potential issue" was completely eliminated before the goods were packed. After passing the re-inspection, the goods were successfully shipped and arrived at the port on time.

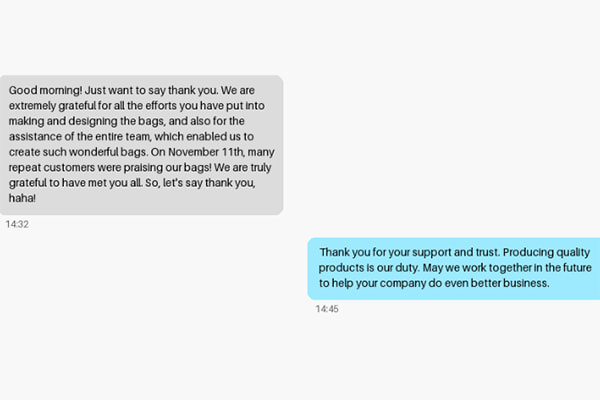

After the product was launched for sale, customers reported that their consumers highly praised the workmanship and texture of the product. The repurchase rate and repeat customers continued to increase, and the sales curve rose steadily. All these successes were not accidental but attributed to the efficient quality system we established: from strict raw material inspection, first-piece approval, in-process inspection during production, full inspection before shipment, to rapid problem closure and archiving management, we ensured that every link was perfect.

Just as we firmly believe, the guarantee of quality does not come from the lowest price, but from a sound management system and a resolute service attitude. We insist on testing our products in real usage scenarios and raising standards at key touchpoints, openly and transparently presenting problems and fully presenting the evidence chain, and establish detailed records for every improvement. It is precisely this ability to prevent risks before shipment that helps our clients win a competitive edge in the demanding market with more stable quality.

If you are looking for a partner who is strict about details, responsible for problems, and transparent about processes, we are willing to use every verifiable full inspection and every documented improvement record to safeguard the "tangible and visible" quality bottom line for your brand. Because in the real market, what consumers repeatedly choose is never the lowest price, but the outstanding quality that stands the test of time.

Keywords: quality assurance

Originally published 15 Nov 2025, updated 15 Nov 2025.